In the dynamic landscape of construction and resource development, directional drilling has risen as a crucial technology that transforms how we handle subsurface projects. Directional Drilling Northern Ireland -edge drilling method allows for precise drilling at multiple angles, enabling approach to difficult-to-access resources and minimizing environmental impact. Whether it be oil and gas discovery or the installation of utilities beneath bustling urban centers, directional drilling is a game-changer that offers countless advantages over traditional drilling techniques.

As we explore the world of directional drilling, this foundational guide will outline the key concepts, historical progress, and applications across multiple industries. From the intricate processes that explain how directional drilling works to success stories highlighting its efficacy in real-world applications, we will explore the benefits and challenges of this technology. Join us as we discover how directional drilling is not just a method, but a crucial component in building a sustainable future for our infrastructure and energy requirements.

Comprehending Directional Boring

Directional boring is a technique which allows drillers to produce holes that divert from the vertical path. Such a technique gives the ability to access below-ground resources more effectively and is widely used in multiple industries, including petroleum and natural gas, services, and sustainable energy. In contrast to traditional vertical drilling, which constrains accessibility to locations directly under the well location, directional boring gives versatility in targeting specific locations, minimizing ground interference and optimizing material harvesting.

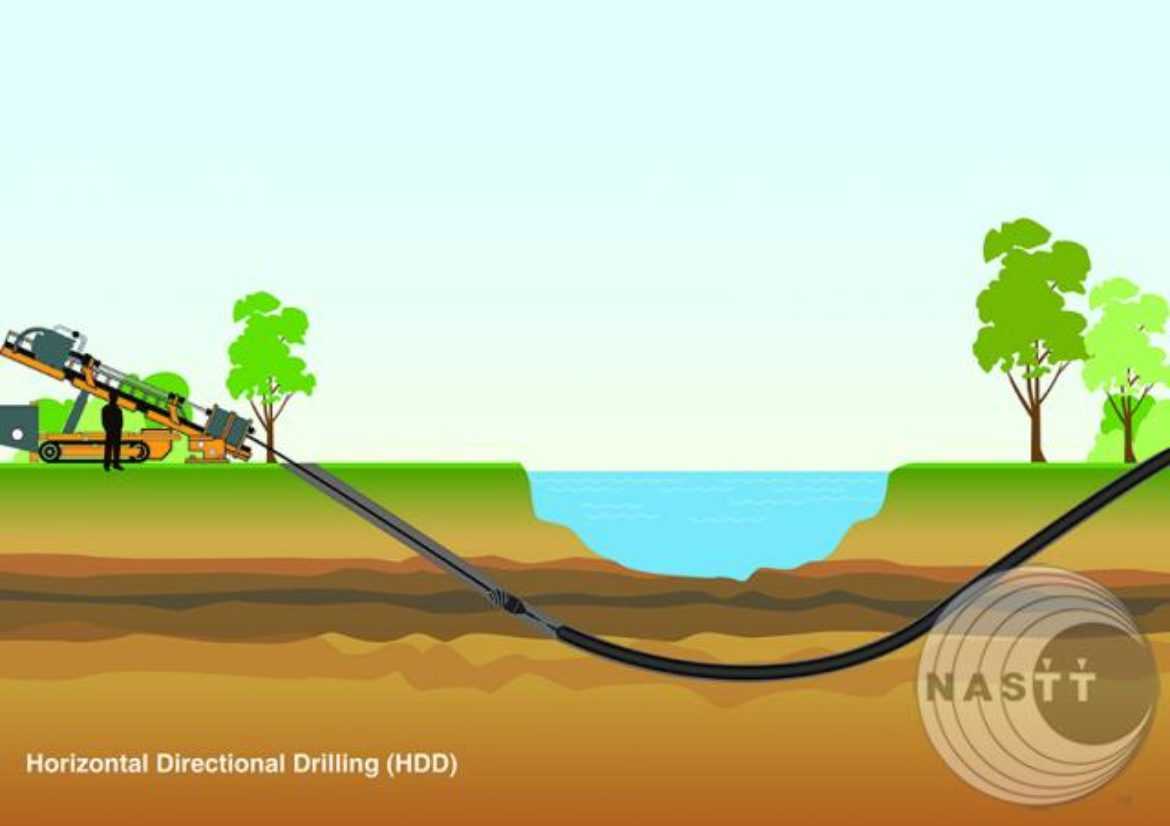

An of the main advantages of directional drilling lies in its potential to navigate complicated earth formations. With modifying the tilt of the bore, drillers can avoid hindrances such as lakes and rivers, urban infrastructure, or environmentally sensitive areas. This capability not just enhances the protection and efficiency of boring processes and also lessens the natural impact and ground consequence. Consequently, directional boring has become an essential instrument for organizations aiming to improve sustainable practices during meeting their functional targets.

Furthermore, technological advancements have remarkably developed the practices associated with directional boring. Innovations in drilling tools, tracking systems, and programs have boosted precision and shortened the time needed for drill initiatives. Such improvements allow teams to prepare and perform additional complex and exact initiatives, making sure that resources are obtained effectively and upholding strict safety protocols. To summarize, grasping directional boring stays vital for professionals who want to capitalize on its advantages in multiple uses.

Advantages of Directional Boring

Directional drilling offers numerous benefits over conventional vertical drilling techniques. One of the key advantages is the ability to reach several targets from a single drilling site. This approach reduces the number of drilling sites needed, which not only conserves on costs but also minimizes environmental effects and terrain disturbance. As a result, companies can function more efficiently while keeping a emphasis on sustainable practices.

Another significant benefit is the reduction of surface interference. Directional and Horizontal drilling allows operators to maneuver around barriers such as buildings, roads, and natural features, which is especially critical in city environments. By drilling below ground, the technique can place infrastructure and ducts without disturbing the topography, thus preserving the stability of current systems and the surrounding ecosystem.

Additionally, directional boring can be considerably cost-effective in the long term. Although the initial investment in equipment and supplies may be higher, the lowered need for several drilling locations and the capability to bore more precisely often lead to decreased overall project expenses. This effectiveness can result into substantial savings in both time and assets, making directional drilling an ever more attractive choice for multiple industries, including petroleum, energy services, and renewable power.

Upcoming Developments in Drilling Direction

The future of directional drilling is ready for major transformation as tech innovations continue to develop. Advancements in AI and automation are improving drilling accuracy and efficiency. These technologies allow for live data evaluation, allowing operators to take timely decisions promptly and modify drilling settings on-the-fly. As these systems become more interconnected, we can expect to see a marked increase in productivity and a reduction in operational expenses.

Another major trend is the incorporation of digital solutions, including specialized software and advanced sensors. These technologies allow for better planning, monitoring, and troubleshooting throughout the drilling process. By leveraging data analysis and ML, businesses can optimize bore paths and anticipate potential issues, thus reducing the likelihood of expensive delays or job failures. The shift toward digital technologies is not only rendering the processes more effective but also creating the way for safer and more eco-friendly drilling practices.

Finally, the emphasis on sustainable practices is changing the landscape of drilling direction. As companies are pressed to adopt environmentally friendly practices, this method offers a approach that minimizes surface disruption and ecological effects. Companies are now focusing on developing methods that improve efficiency while also addressing environmental concerns. This shift toward sustainability will likely fuel the adoption of new techniques, ensuring that this field remains pertinent in an evolving market.